Production mills

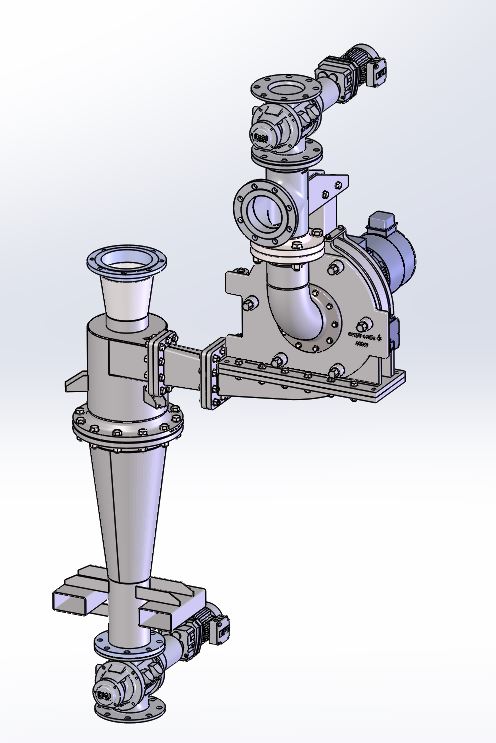

The Peppink AN, W and M type mills can all be used as production mills. The Peppink W mills can also be designed as a pen mill. The capacity of the Peppink production mills can vary from 10 kg to many tons per hour, depending on the type of mill. Peppink Production Mills are designed to be able to mill 24/7 in a continuous production process.

On this page you will find more information about the different types of Peppink production mills.

Peppink AN Mills

The Peppink AN Mills are made of high quality cast iron or cast stainless steel. Mills manufactured from the latter material comply in an ATEX zone 22 and are then supplied 'Explosion Pressure Shock Resistant' up to 0.5 bar.

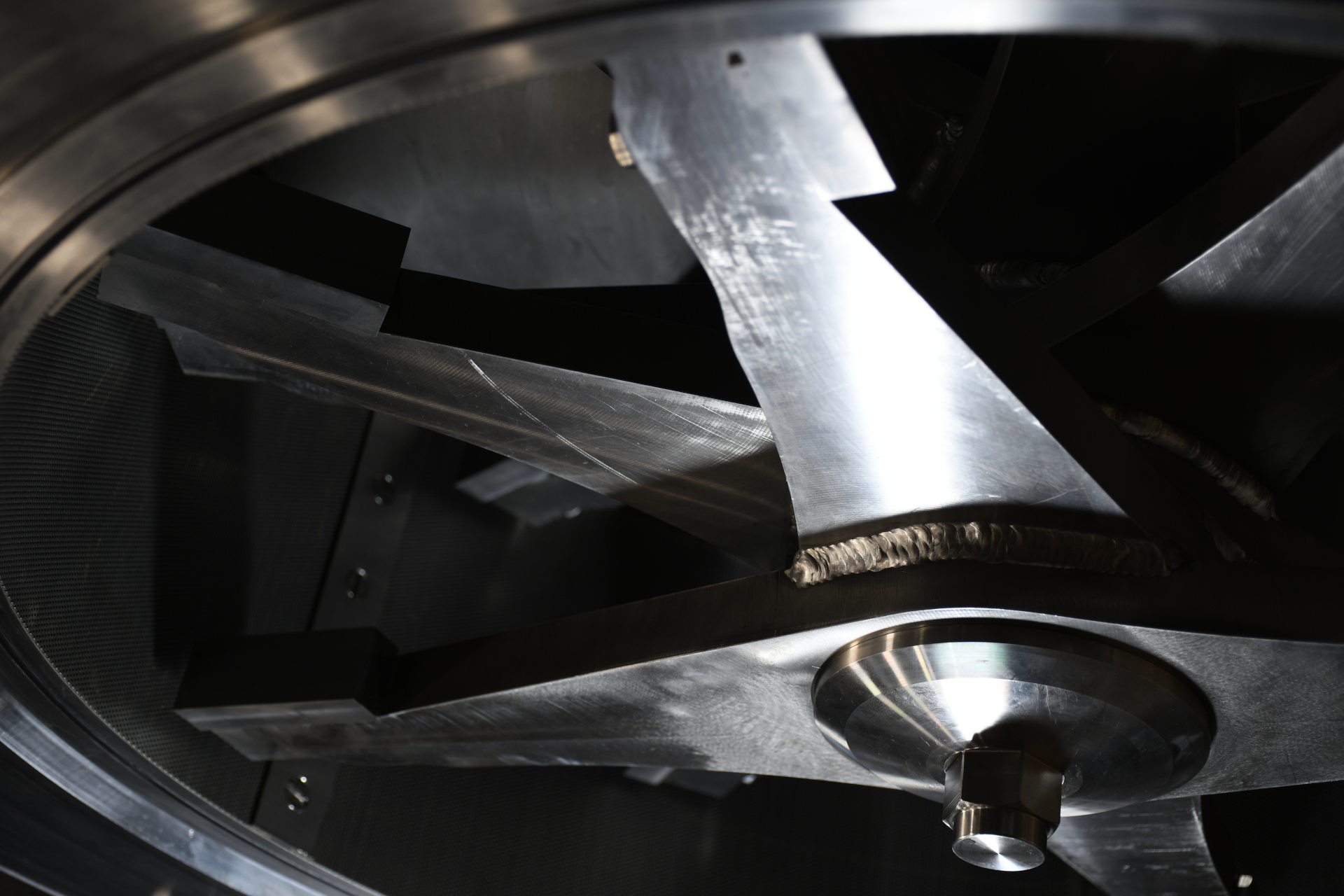

With the Peppink AN beater cross mills, the product is fed into the milling chamber just below the mill axis. Since there is an under pressure here as a result of the rapidly rotating beater cross, the product is sucked into the mill and reduced in size. The milled product is then blown out of the mill through a sieve mounted all around the milling chamber and collected in, for example, a hopper.

The mill is driven by a flange motor. The Peppink AN beater cross mills can be supplied with a number of options or alterations, including the method of supply and discharge or the control of the mill. This document provides an overview of the different dimensions of the AN mills.

Interested, or do you have a question? Do not hesitate to contact us!

Peppink 200 AN

- Capacity: max. 100-500 kg/h

- Milling Chamber: ø200 mm x 38 mm

- Fineness: approx. 250 - 20 μm

Peppink 300 AN

- Capacity: max. 200-800 kg/h

- Milling Chamber: ø310 mm x 42 mm

- Fineness: approx. 250 - 20 μm

Peppink 550 AN

- Capacity: 500 - 2.500 kg/h

- Milling Chamber: ø565 mm x 100 mm

- Fineness: approx. 250 - 20 μm

The capacity depends on the fineness and the product.

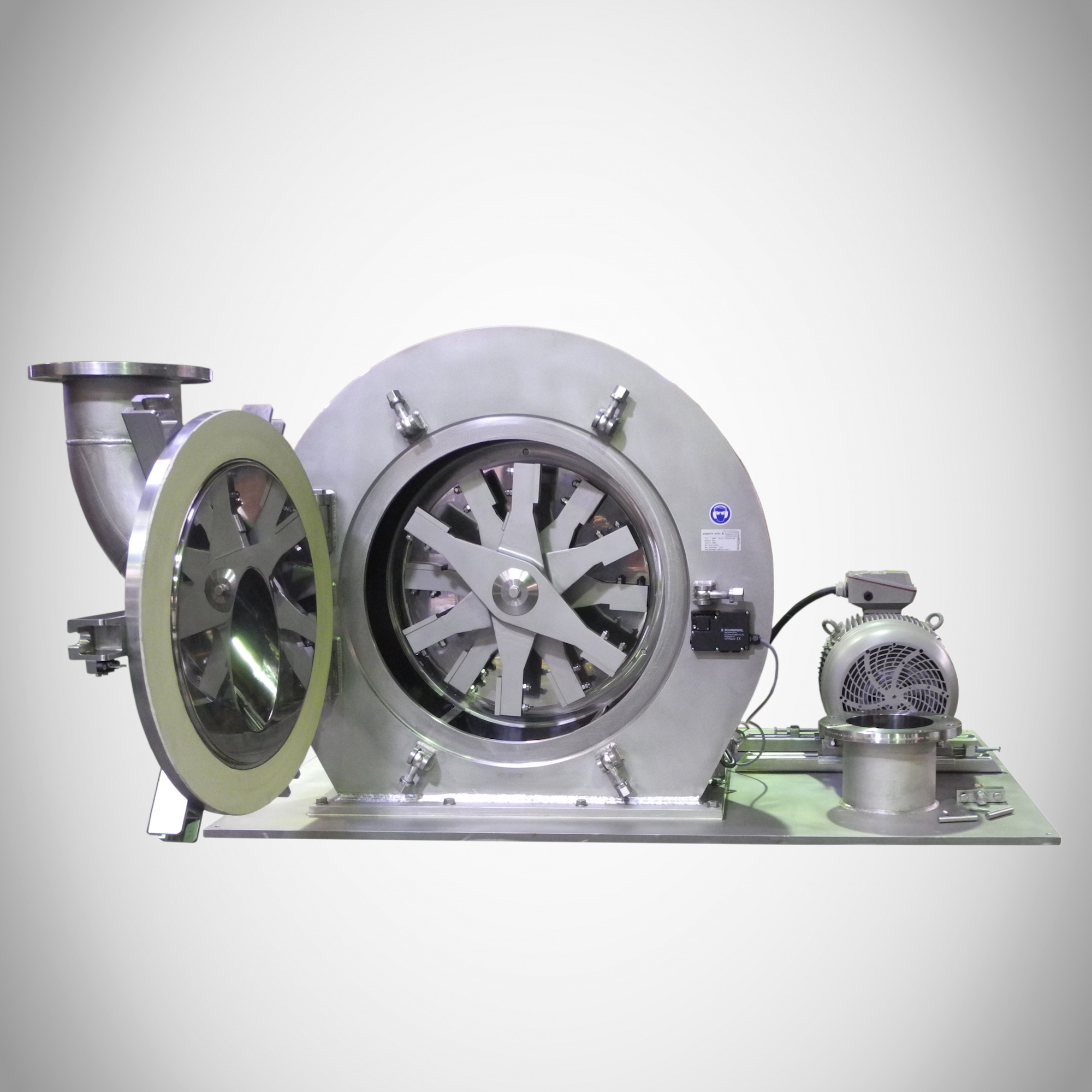

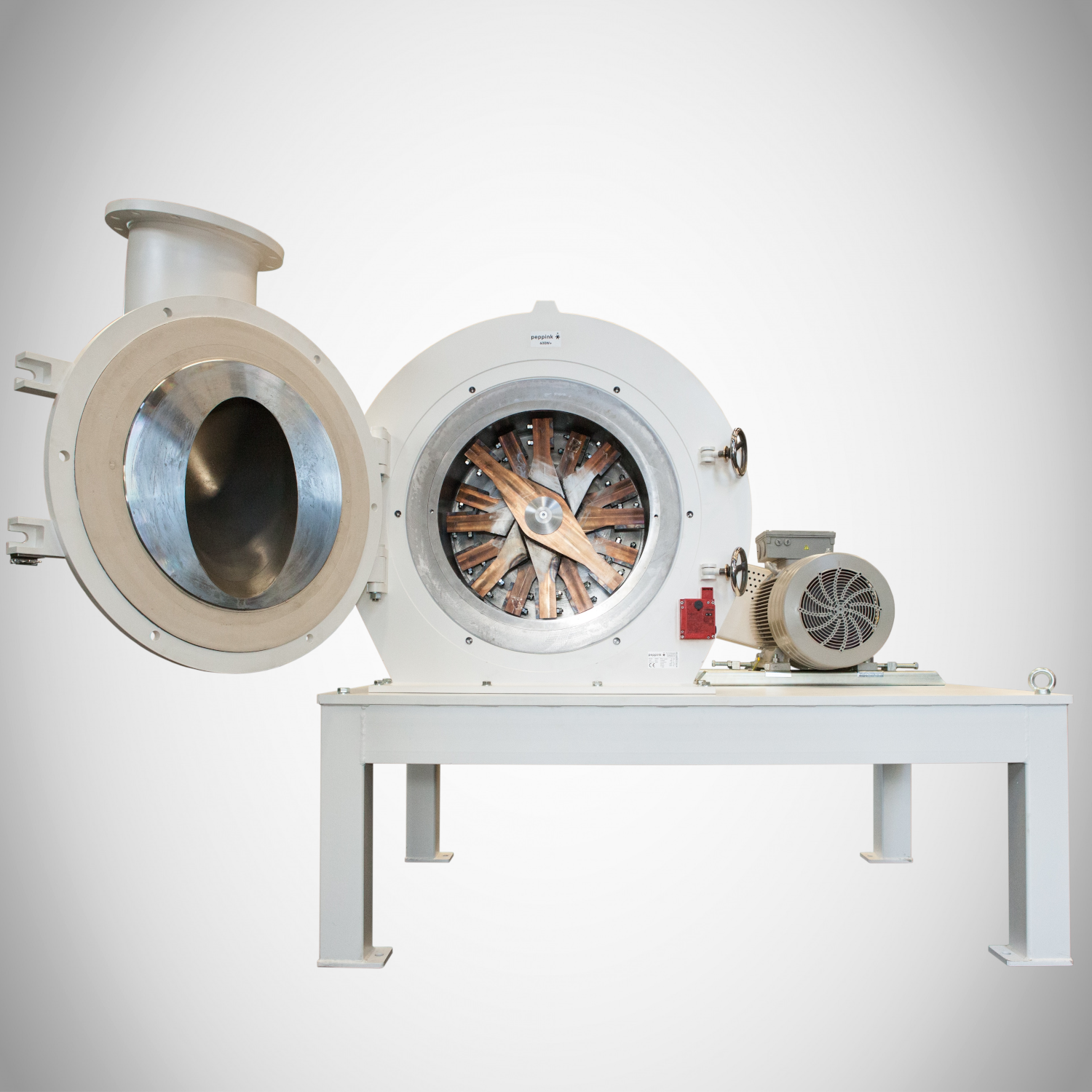

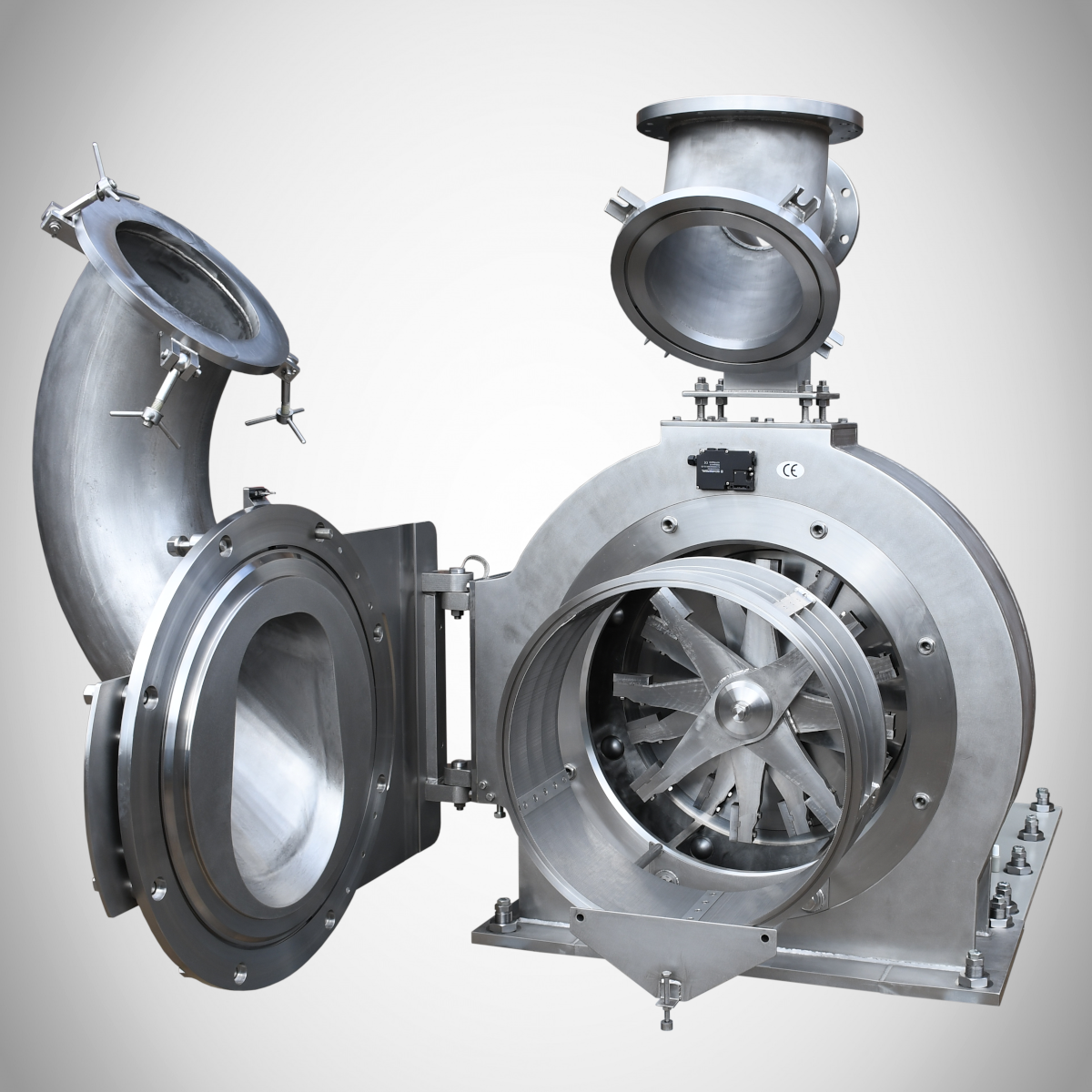

Peppink W Mills

In addition to the standard AN mill, Peppink produces the larger Peppink W production mills. These welded mills are almost exclusively suitable for ATEX zone 22 and also zone 21. This means that the Peppink W mills are 'Explosion Pressure Shock Resistant' from a minimum of 0.5 bar up to a maximum of 10 bar. The Peppink W mills can also be manufactured Explosion Pressure Resistant in a special weighted version.

The operation of the Peppink W beater cross mills is the same as that of the Peppink AN beater cross mills: the product is fed into the milling chamber just below the mill axis. Since there is an under pressure here as a result of the rapidly rotating beater cross, the product is sucked into the mill and reduced in size. The milled product is then blown out of the mill through a sieve mounted all around the milling chamber and collected in, for example, a hopper.

The Peppink W type mills are usually supplied as a beater cross mill, but can also be supplied as a pin mill if desired.

This document provides an overview of the different sizes of the Peppink W mills.

Interested, or do you have a question? Do not hesitate to contact us!

Peppink 350 W

- Capacity: max. 400-1.500 kg/h

- Milling Chamber: ø360 mm x 80 mm

- Fineness: approx. 250 - 20 μm

Peppink 600 W

- Capacity: max. 3.000-7.000 kg/h

- Milling Chamber: ø620 mm x 220 mm

- Fineness: approx. 250 - 20 μm

Peppink 600 W/16

- Capacity: max. 3.000-10.000 kg/h

- Milling Chamber: ø620 mm x 235 mm

- Fineness: approx. 250 - 20 μm

Peppink 700 W

- Capacity: max. 4.000-12.000 kg/h

- Milling Chamber: ø720 mm x 235 mm

- Fineness: approx. 250 - 20 μm

The capacity depends on the fineness and the product.

Peppink M Mills

Besides the Peppink AN and Peppink W beater cross mills, Peppink also offers Peppink M mills.

With the Peppink M mills, the product falls on the rotating rotor and vaccuum is often generated by an additional fan. The Peppink M mills are available in 2 variants; Peppink M Hammer Mills and Peppink M Beater Cross Mills. The difference is that in hammer mills, the hammers are "loose" on the mill shaft, where in the beater cross mill, the arms are attached to the shaft. These Peppink M mills are built on the basis of a standard model series with a rotor of 200, 300 or 400 mm and can of course also be adapted to specific customer requirements.

The Peppink M type mills are very suitable for milling tough, fiber-rich products. The Peppink M mills are available in different sizes, this document provides an overview of the different dimensions of the M mills.

Interested, or do you have a question? Do not hesitate to contact us!

older production mills

all parts of these mills can still be supplied