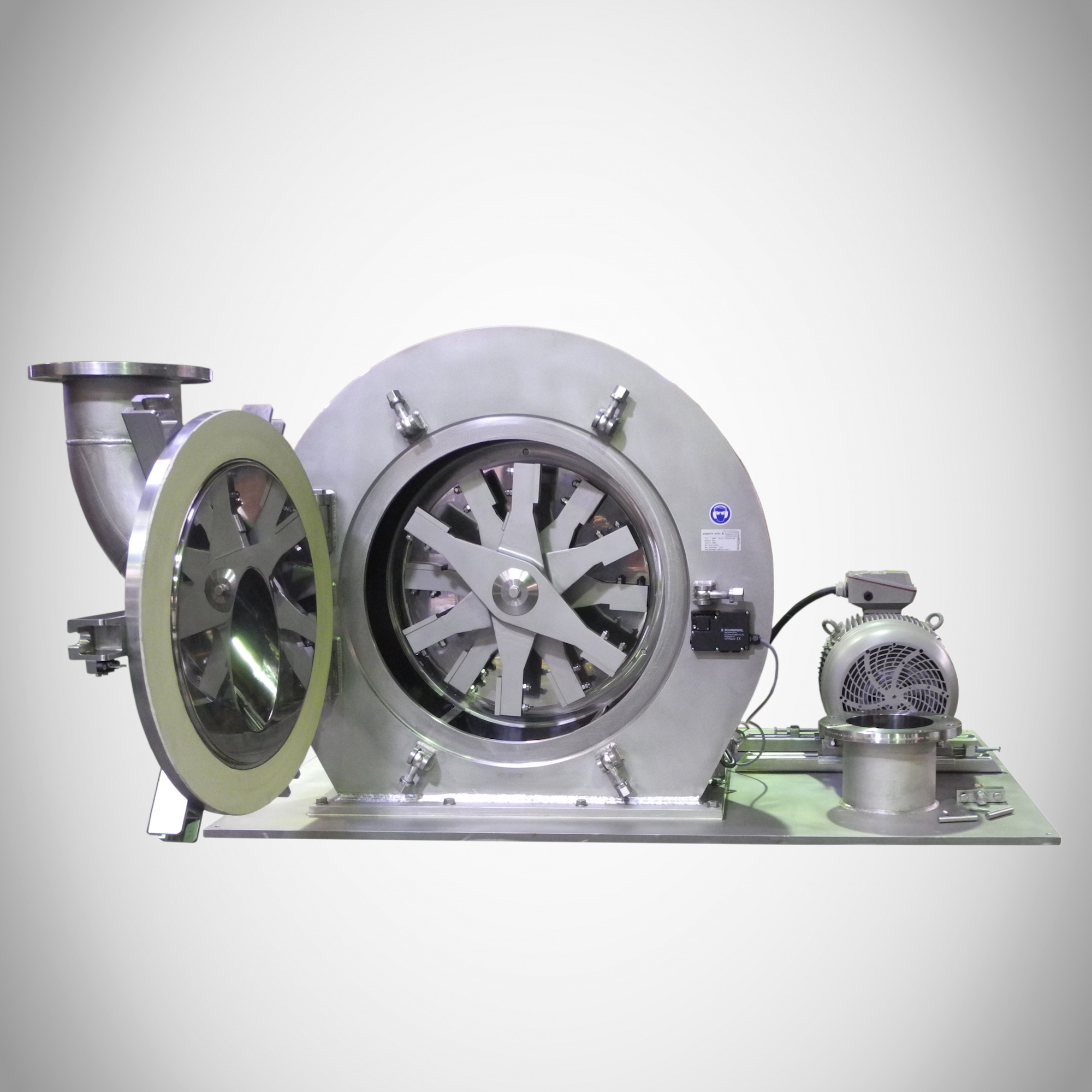

Peppink 600 W mill

The Peppink 600 W beater cross mill is used in the process or food industry and is ideal for continuous operation. Due to its wide milling chamber, a very high capacity can be achieved.

Flange connections for air transport can be mounted for continuous transport through the mill. For discontinuous transport, a large spout is installed at the bottom of the mill, to which a big bag or a similar collection system can be attached.

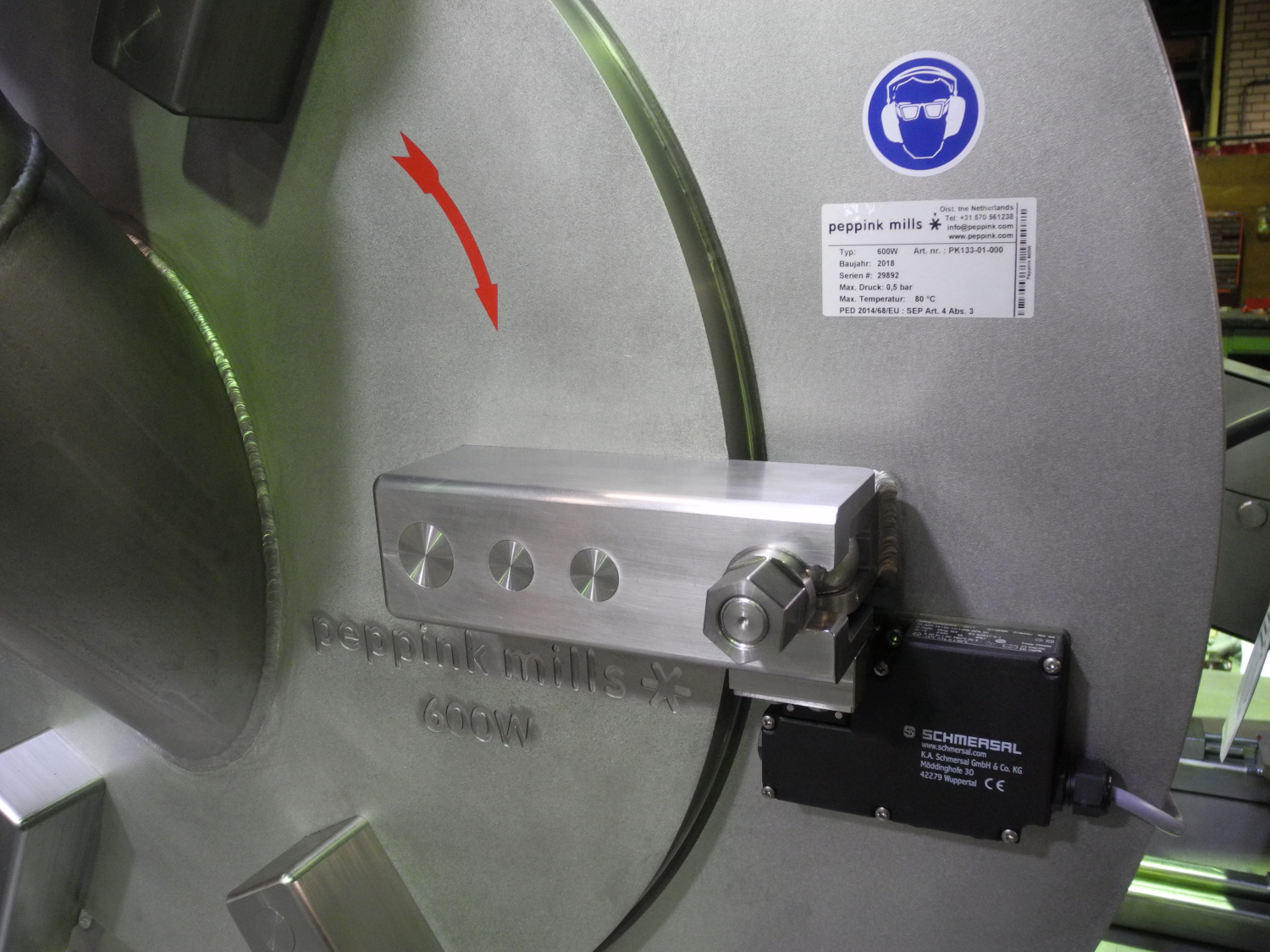

An automatic lock is mounted on the mill door for a safe working environment. In addition, the Peppink 600 W mill can be ATEX certified. The beater cross and sieve plates are easy to replace or exchange.

Specifications Peppink 600 W

| Mill dimensions (AxBxC) (mm) | 1110 x 1200 x 1150 |

| Mill weight | approx. 1.600 kg |

| Mill chamber | ø620 mm x 220 mm wide |

| Mill inlet | Front |

| Mill RPM | 750 – 5.500 rpm |

| Max. milling speed | 173 m/s |

| Motor | 22 / 30 / 37 kW, 400/690V, 50 Hz |

| Transmission | Flange motor / Belt drive |

| Mill house | Welded steel, stainless steel or stainless steel sanitary ware |

| Sieve cage | Steel or stainless steel, removable |

| Sieve surface | 360° (± 3.039 cm²) |

| Sieve plates | Interchangeable, perforation of your choice |

| Beater cross | Hardened steel or stainless steel, 6 or 12 arms, possibly with wear tips |

| Supply product | Vibrating chute, screw or air transport |

| Exit product | Mobile collection bin or air transport |

| Options | Base frame, fixed or mobile |

| Available in stainless steel |