Peppink mills

Peppink produces both production mills and laboratory mills.

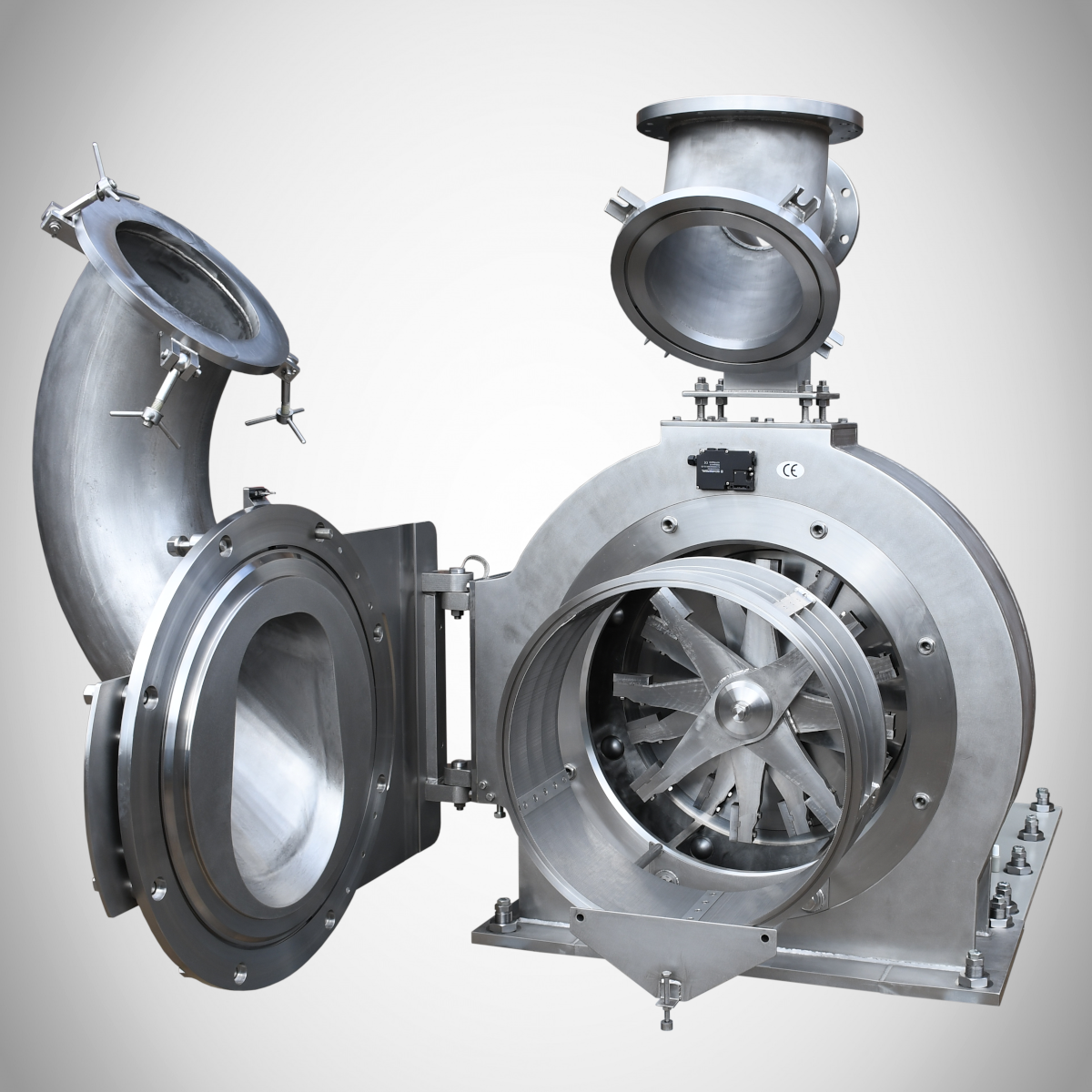

Peppink production mills are used in production processes to mill different products. This can mean milling tens of kilograms per hour, or milling several tons of product per hour. Peppink production mills are designed to allow 24/7 milling in a continuous production process.

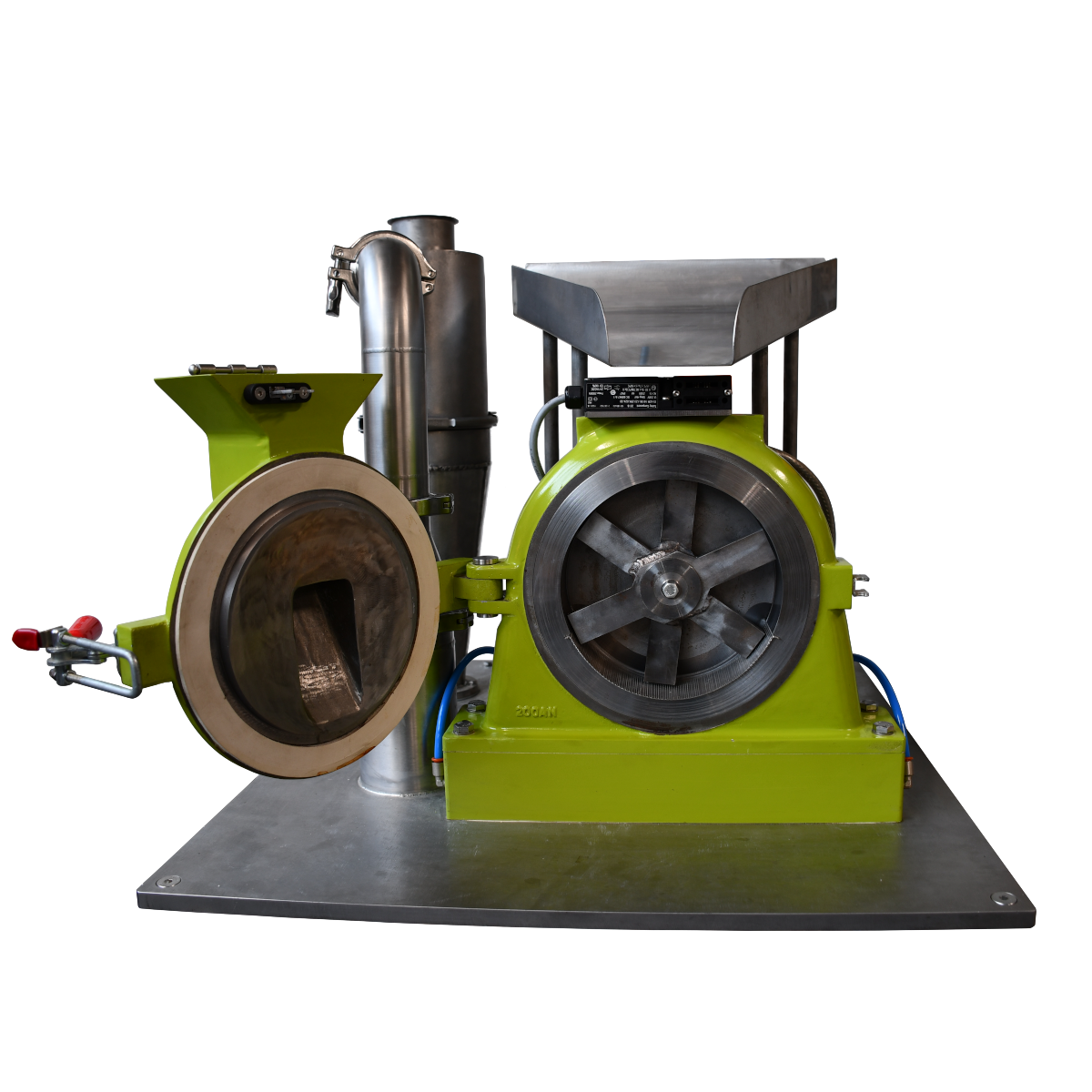

In laboratories, many different products are milled to be researched. No contamination must arise between these different samples. Peppink laboratory mills are designed so that they are easy to clean or clean themselves after milling a sample.

The selection of the type and size of the Peppink mill is made based on the properties of the product to be ground, such as moisture & fat content, the desired production capacity, explosion hazard, and other customer requirements.

Peppink laboratory mills are used for milling samples for (NIR-) analysis. The Peppink laboratory mills differ in the number of samples that they can mill per hour.

Contamination between samples is low, because Peppink laboratory mills are easy to clean, or self-cleaning using compressed air.

Peppink production mills are used for milling a wide variety of products in the food & non-food, pharmaceutical, recycling and chemical industry. Peppink supplies various types of production mills, which in combination with a product collection/hopper under the mill, a cyclone/filter installation and product supply form the desired milling-installation.