Milling-installations

Our goal at Peppink is to convert your question into the optimal solution. The focus is on safely achieving the desired final fineness and capacity. Peppink Mills takes care of the entire process for you: design, production, installation and service. We take care of the installation in collaboration with our specialized partners.

At Peppink we know that every product and customer is different. Thanks to our own Peppink engineers, we can respond to this with great flexibility and customer focus.

It often happens that we specifically adapt our standard models to the wishes of a customer or even design an entirely new mill installation. In this way, we at Peppink are able to supply mill installations that exactly match your needs..

Complete installations

The Peppink team has the capacity to execute entire projects from design to installation. All installations are carried out to customer-specific requirements and wishes.

Peppink has the knowledge of various accessories for mills, such as cyclones, filter installations, metal detection systems, etc. This enables Peppink to offer you a complete installation that exactly matches your wishes and requirements.

Components

Peppink Mills designs and sells mills that are produced at the same address by sister company Machinefabriek G.R. Veerman.

Thanks to the close cooperation between Peppink's design department and the production department of Machinefabriek Veerman, Peppink can immediately test the manufacturability of its designs. The extensive machinery of Machinefabriek Veerman means that Peppink can develop and produce many products cheaply and quickly.

Following are several examples of additional components that Peppink can supply:

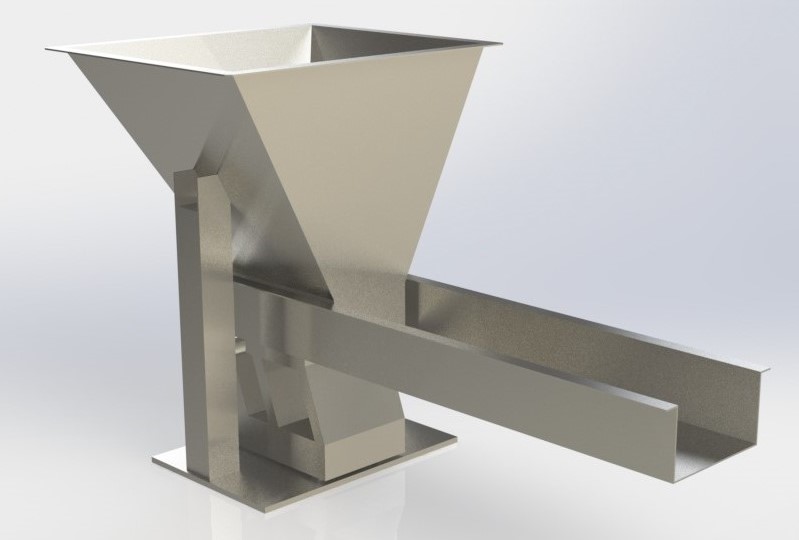

Dosing components

A mill must reach the set milling speed before product is fed into the milling chamber. It is important that the product input is regular and controlled. Peppink produces several components, such as vibrating chutes, transport screws, flexible hoppers with screws or rotating locks, which all ensure that the input product is dosed gradually. Peppink advises and delivers the best solution depending on product properties and ATEX zoning.

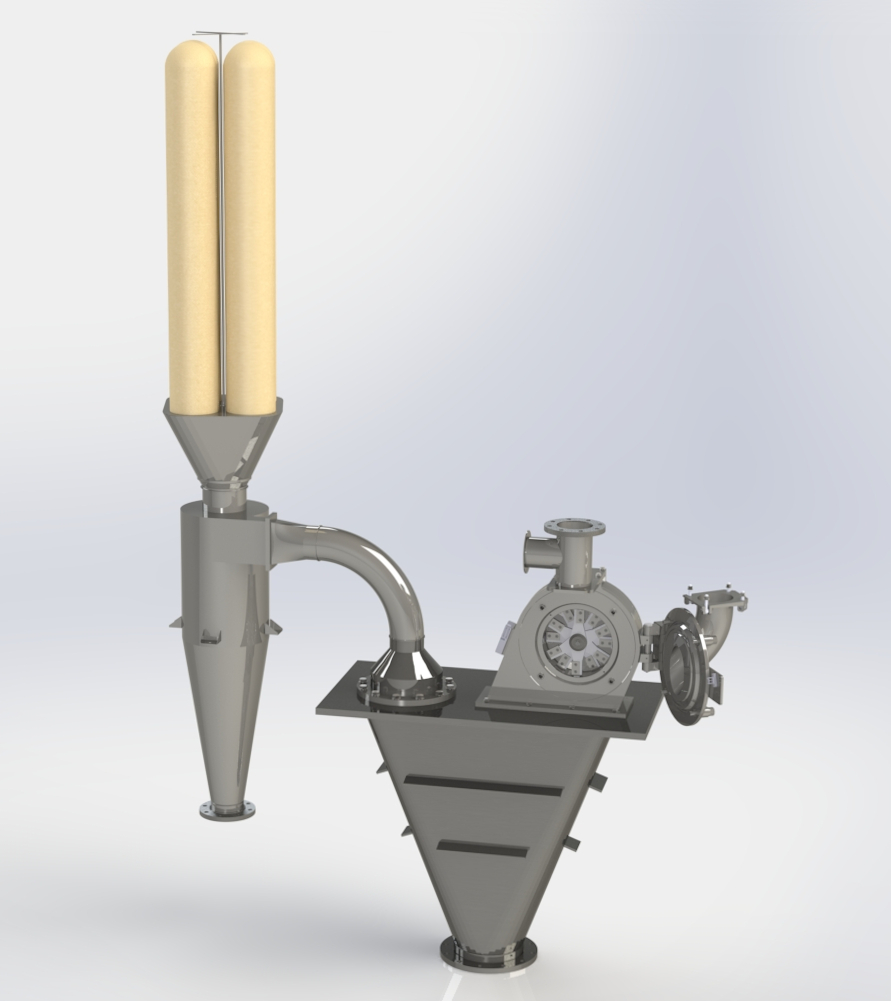

Filter installation

The purpose of a filter installation is to filter the air generated by the mill, coming from the cyclone or from the hopper on which the mill is mounted.

Peppink advises which type of filter installation can best be used for a particular product. The installation will comply with the ATEX zone resulting from the user's risk analysis.